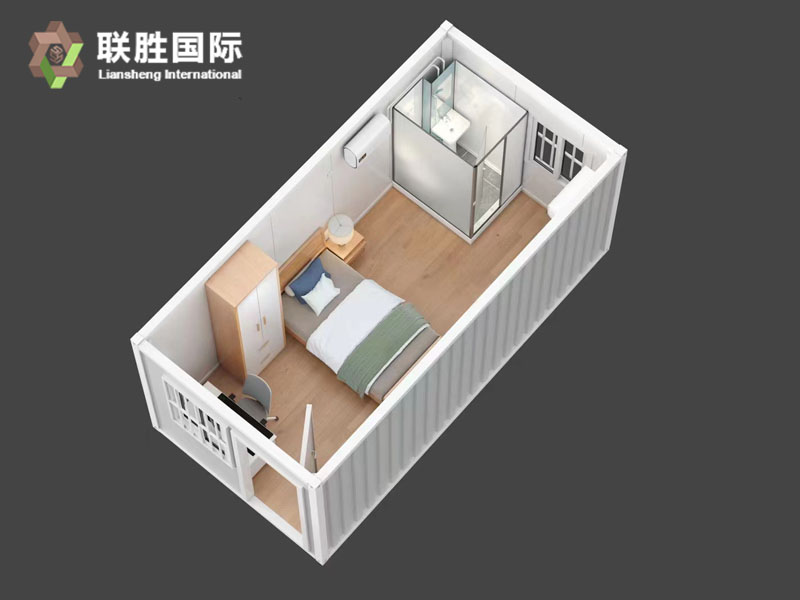

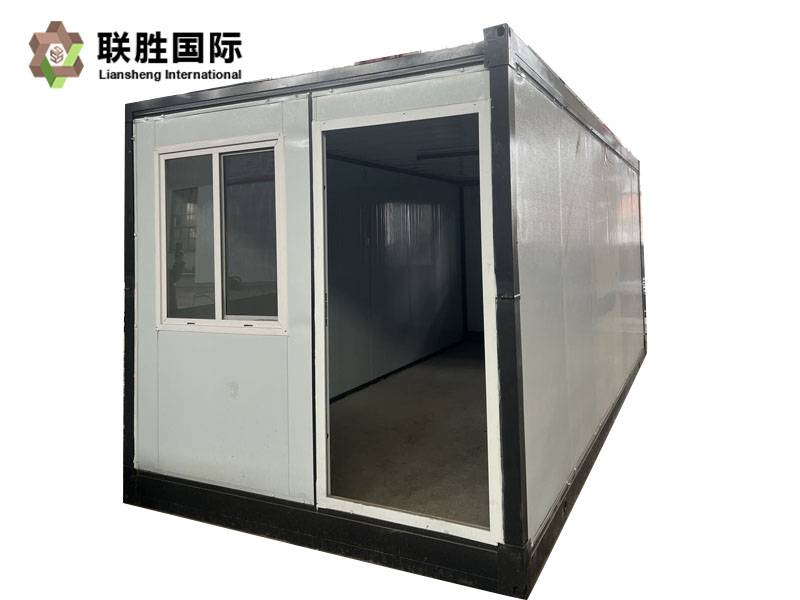

Prefab Folding Container House

Send Inquiry

As one of the Prefab Folding Container House leading suppliers and manufacturers in China, the company ensures a seamless blend of durability, functionality and cost-effectiveness in its Prefab Folding Container House products. Whether for residential, commercial or industrial applications, Lian Sheng International’s Prefab Folding Container House demonstrates the latest advancements in modular construction technology, making it a reliable choice for projects of varying sizes and requirements.

Prefab Folding Container House Advantage:

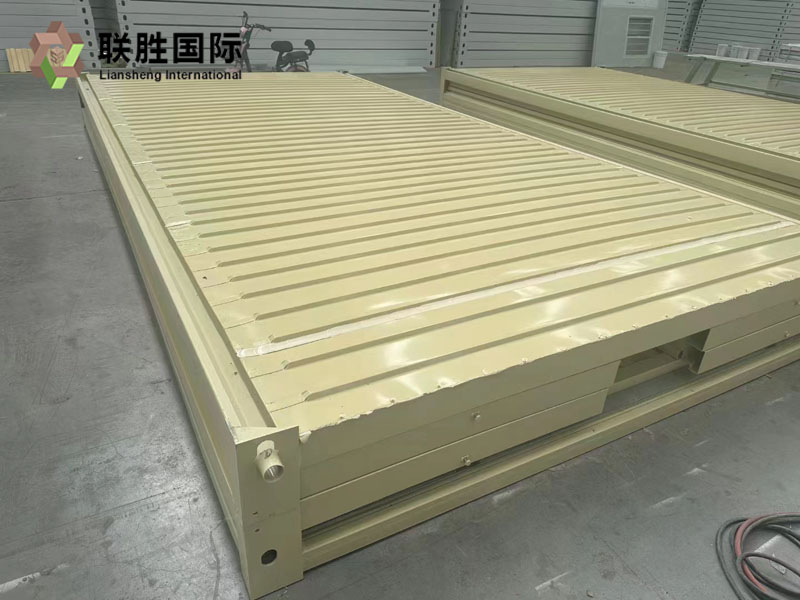

1. Material: The main structural material of Prefab Folding Container House is galvanized steel, which has good corrosion resistance and tensile strength and can effectively resist the influence of various natural environments.

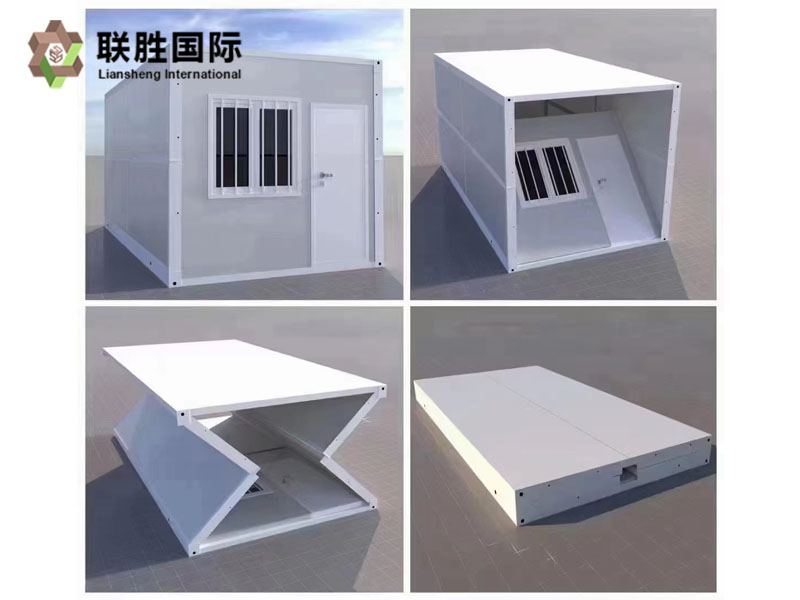

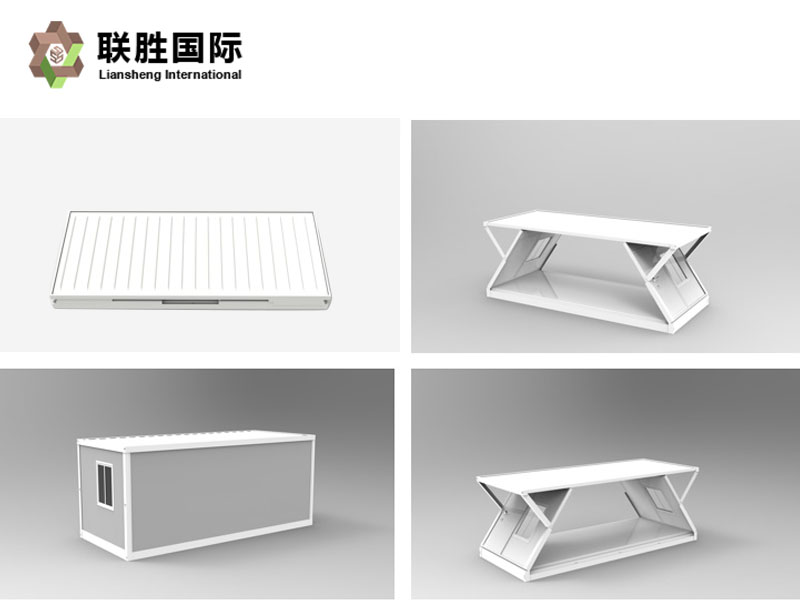

2. Prefabricated modules: All parts of the house are prefabricated in the factory, including walls, floors, roofs, etc., and then transported to the site for assembly. This prefabrication method can greatly shorten the construction period and improve construction efficiency.

3. Rapid construction: Since each module is prefabricated in the factory, only simple assembly work is required on site, so the construction speed is very fast. Compared with traditional buildings, the Prefab Folding Container House can be shortened by more than half.

4. Energy saving and environmental protection: Prefab Folding Container House adopts lightweight materials and high-efficiency energy-saving design, with low energy consumption and good thermal insulation performance. In addition, the construction process of prefabricated modular buildings produces less waste and has a smaller impact on the environment.

5. Good seismic resistance: The galvanized steel frame has high tensile strength and ductility and can effectively resist the effects of natural disasters such as earthquakes. At the same time, the structural design of prefabricated modular buildings is more reasonable, which can better disperse earthquake forces and improve the seismic performance of the building.

6. High flexibility: Prefab Folding Container House can be customized according to actual needs to meet different functional and space requirements. In addition, Folding Container Houses are relatively easy to dismantle and modify, offering high flexibility.

| Folding Container House Configuration Table | ||||

|---|---|---|---|---|

| Type | Specification | Material name | Size | Thickness(mm) |

| Size | External Size(mm) | * | 5800(L)*2480(W)*2500(H) | * |

| Internal Size(mm) | * | 5640(L)*2320(W)*2400(H) | * | |

| Folding Size(mm) | * | 5800(L)*2480(W)*340(H) | * | |

| Qty(kg) | * | 850 | * | |

|

Frame structure |

Top frame | Q235B Rectangle square tube | 37*37 | 1.1 |

| Q235B Rectangle square tube | 20*40 | 1.1 | ||

| Q235B Rectangle square tube | 60*60 | 1.5 | ||

| Hanging head board | 140*155 | 3.0 | ||

| P-type Tube | 35*78 | 1.1 | ||

| Glass Wool | 75 | |||

| Ceiling Panel | YH24-231-961 | 0.18 | ||

| Panels with sides 6 meters long | Process Guard Panel | 120 | 1.8 | |

| U-Shaped Groove | 50 | 1.1 | ||

| P-type Tube | 40*60 | 1.2 | ||

| Hinge | High strength | |||

| Panel | Double sided | 50 | ||

| Galvanized Corners | 0.65 | |||

| D Type Adhesive Atrip | Reinforced adhesive strip 12*10 | |||

| Panels with sides 3 meters long | P-type Tube | 35*78 | 1.1 | |

| U-Shaped Groove | 65 | 1.1 | ||

| L-type Tube | 60*80 | 1.5 | ||

| Panel | Double sided | 65 | ||

| Window | 920*920 | 4 | ||

| Door | 970*1970 | 70 | ||

| D-type black tape | Reinforced adhesive strip 12*10 | |||

| Top frame | Custom bottom beam (galvanized panel) | 140*60*6m | 1.2 | |

| 60*80 | 1.5 | |||

| corner piece plate | 140*180 | 3.0 | ||

| Hinge | High strength | 1.7 | ||

| Q235B Rectangle square tube | 37*37 | 1.2 | ||

| Flooe | 1.5 | |||

| Top of container | Overall frame painting | Paiting | ||

| External top panel | Color substrate 0.36mm*1.2m*2.95m*2 pce+0.36m*1m*2.95m*4 pce | |||

| Internal ceiling | Color steel panel V831/0.18mm | |||

| Panel | 6 meter length panel | 50mm composite panel 0.16mm+rock wall(50kg/m³)±0.03mm | ||

| 3 meter length panel | 65mm composite panel 0.16mm+rock wall(50kg/m³±0.03mm | |||

| Floor | Fireproof glass magnesium floor 15mm | |||

| Electrical system | Electrical wiring is installed in strict accordance with moisture-proof specifications, and all electrical products comply with CE certification. Connect the circuit according to the circuit engineering specifications. Indoors: 4² national standard soft copper wire for incoming wire, 1 20A circuit breaker, 2.5² socket incoming wire, 1 five-hole single-open socket, 1 ten-hole socket, and 1 LED light. | |||

| Security doors | High quality security door (warm white) size:970mm*1970mm | |||

| Window | 920*920Single glass sliding window plastic steel window,thickness 4mm(warm white) | |||

| Quality assurance | One year(CN) | |||

| Roof load-bearing | 1.0 KN/m2 | |||

| Floor load-bearing | 4.2 KN/m2 | |||

| Walkway load-bearing | 2.0 KN/m2 | |||

| Wall pressure | 0.5 KN/m2 | |||

| Fire-proof level | Level-A | |||

| Earthquake-proof level | Level-8 | |||

| Wind-proof level | Level-10 | |||

| Remark:40HQ can hold 10 sets | ||||

| Z-Flat Folding Container House Config | |||||

| Specifications and Sizes: |

External Size:5800(L)*2500(W)**2500(H) mm Internal Size:5700(L)*2400(W)*2320(H) mm Folding Size:5800(L)*2500(W)*410(H) mm Total Weight :1200(kg) |

||||

| NO | Material | Type | Thickness(mm) | Unit | |

| 1 | Bottom Structure | Q235 galvanized square pipe | 40*40*6m | 1.30 | pcs |

| 2 | Q235 galvanized square pipe | 20*40*0.9m | 1.30 | pcs | |

| 3 | Q235 galvanized square pipe | 20*20*5.68m | 1.30 | pcs | |

| 4 | galvanized square pipe | 60*60*5.8m | 1.30 | pcs | |

| 5 | galvanized square pipe | 60*60*2.48m | 1.30 | pcs | |

| 6 | Angle steel | 40*40*5.64 | 2.00 | pcs | |

| 7 | 30*30*5.64m | 1.30 | pcs | ||

| 8 | 30*30*2.32m | 1.30 | pcs | ||

| 9 | Color steel corrugated board | nano-coating | 0.50 | pcs | |

| 10 | rookwool | 11.6m*1.24m | 50.00 | m | |

| 11 | celling panel | 831 color steel tile | 0.25mm | pcs | |

| 12 | Location of the left and right wall panels | L-shaped colunmn | 1.09m | 2.00 | pcs |

| 13 | 1.110m | 2.00 | pcs | ||

| 14 | galvanized 215 P-shaped pipe | 30*55*5.8m | 1.30 | pcs | |

| 15 | galvanized 215 P-shaped pipe | 2270mm | 1.30 | pcs | |

| 16 | galvanized hinge | high strength | pcs | ||

| 17 | wall panel | 960*2205*50 | 0.3/0.3 | pcs | |

| 18 | D-shaped adhesive strip | 2.5m | pcs | ||

| 19 | D-shaped adhesive strip | 5.8m | pcs | ||

| 20 | Location of front and rear wall panels | galvanized 235 P-shaped pipe | 2.43m | 1.30 | pcs |

| 21 | 2.31m | 1.30 | pcs | ||

| 22 | wall panel | 960*2125*50 | 0.3/0.3 | pcs | |

| 24 | window | 930*1100 | 0.40 | pcs | |

| 25 | door | 970*1980 | good quality-security door | pcs | |

| 26 | adhesive strip | 2.5m | sealed against dust | pcs | |

| 27 | bottom structure | customized galvanized square pipe |

60*120*5.8m 60*60*5.8m |

1.30 | pcs |

| 28 | 60*120*2.32m | 1.30 | pcs | ||

| 29 | 60*60*2.32 | 1.30 | pcs | ||

| 30 | hinge | high strength | pcs | ||

| 31 | Q235B galvanized square pipe | 40*40*2.32m | 1.30 | pcs | |

| 32 | floor | 1125*2355*1.6 | 15.00 | pcs | |

| 33 | leather | t1.0mm | 1.00 | ㎡ | |

| 34 | Overall frame paint | electrostatic spraying/all white plastic powder | pcs | ||

| 35 | Indoor: Incoming wire 2.5² national standard soft copper wire, 1 20A circuit breaker, 1 single switch, 1 five-hole socket, 1 LED light. | Configure electrical wiring and install it in strict accordance with moisture-proof specifications. All electrical products comply with CE certification. Connect circuits according to circuit engineering specifications, | pcs | ||

| Remarks: |

Roof weighing: 1.0KN/m² Walkway weighing: 4.2KN/m² Wall pressure: 0.5KN/m² Fire protection grade: Class A Earthquake resistance level: Level 8 Wind resistance level: Level 10 Service life: 10 years |

||||

| Because the top is a corrugated waterproof structure, it is prohibited to place heavy objects on the top, and secondary construction is prohibited. People must step on the beams when walking. If there are leaks or roof collapse and deformation caused by illegal operations, the manufacturer has nothing to do with it. | |||||